Huayuan Gaoke Cable Co.,Ltd.

400kV High Voltage Power Cable,XLPE Insulated High Voltage Single Core Power Cable,Single Core High Voltage Cable

Huayuan Gaoke Cable Co.,Ltd.

400kV High Voltage Power Cable,XLPE Insulated High Voltage Single Core Power Cable,Single Core High Voltage Cable

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1000 Meter |

Model No.: YJV

Brand: HUAYUAN YONGTONG

Brand: HUAYUAN YONGTONG

Packaging: Drum

Productivity: 1000km/M

Transportation: Ocean,Land,Air

Place of Origin: Beijing,China

Supply Ability: 1000km/M

Certificate: CE,CCC,ISO

HS Code: 8544601900

Port: Tianjin Port,Shanghai Port,Qingdao Port

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

1. GENERAL

This listed specification covers the structure, performance, test and packing information of EHV Power Cable as manufactured by Beijing Huayuan Gaoke cable CO.,Ltd.

Matters not mentioned in this technical specification shall be negotiated by purchaser & supplier. This document confirms the two parties agreement as technical agreement of contract unless otherwise in official written annexes.

2. APPLICALBE STANDARDS

The cable which Beijing Huayuan offered shall be designed, manufactured and tested according to international standards as follows:

| Quality Control Standard | |

| ISO 9001 | Quality Management Systems |

| ISO 14001 | Environmental Management Systems |

| Component Material Standard | |

| IEC 60228 | Conductors of insulated cables |

| Cable Standard | |

| IEC 62067 | Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements |

3.

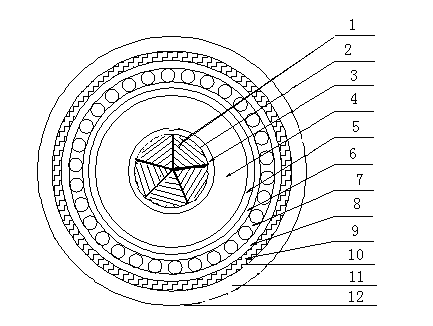

CABLES STRUCTURE for 1C*1400 mm2 Cable

CU/XLPE/CWS/AL-PE/HDPE/ 220/400kV 1×1400/240mm2

| Structure | Nominal thickness mm | Nominal diameter mm |

| 1 Copper conductor(5 Segmental) | / | 45.7±0.8 |

| 2 semi-conductive tape | 0.14 | 46.7 |

| 3 conductor screen(wrapping & extruding) | 2.5 | 50.7 |

| 4 XLPE insulation | 29.0 | 108.7±1.5 |

| 5 Insulation screen | 1.5 | 111.7 |

| 6 semi-conductive water blocking tape | 2.0 | 113.7 |

| 7 Copper wire screen with Copper tape wrapping(gap) | Sectional area 240. mm2(calculation value) | 118.2 |

| 8 semi-conductive water blocking tape | 0.6 | 119.2 |

| 11 Aluminum-polyethylene tape | 0.21 | 119.9 |

| 12 HDPE outer sheath | 6.0 | 131.9 |

| 13 semi-conductive layer(graphite coating) |

| 131.9±3.0 |

4. Guaranteed Technical Particulars

| No | DESCRIPTION | UNIT | VALUEREQUIRED |

| 1 | Manufacturer |

| Beijing Huayuan Gaoke Cable.Co.,Ltd. |

| 2 | Cable size | mm2 | 1400(nominal) |

| 3 | Cable type |

| CU/XLPE/CWS/AL-PE/HDPE |

| 4 | Voltage Grade(U0/U(Um) | KV | 220/400(420) |

| 5 | Reference Standard |

| IEC 62067 |

| 6 | No. and cross sectional area of conductor |

| 1C 1400sqmm |

| 7 | Conductor material |

| Copper |

| 8 | Shape |

| 5 Segmental |

| 9 | Nominal diameter of conductor | mm | 45.7 |

| 10 | Conductor Screen materials |

| Simi-conduction tape + Extruded semi-conducting compound |

| 11 | Nominal thickness of conductor screen | mm | 2.5(wrapping + extruding) |

| 12 | Insulation material |

| super clean XLPE |

| 13 | Nominal thickness of insulation | mm | 29.0 |

| 14 | Nominal diameter over insulation | mm | 108.7 |

| 15 | Insulation screen material |

| |

| 16 | Nominal thickness of insulation screen | mm | 1.5 |

| 17 | Metallic Screen material |

| Copper wire screen with copper spiral binder tape (gap) |

| 18 | Short circuit current rating(t=1.0sec) |

|

|

|

| Of conductor | kA | 201.4 |

|

| Of metallic screen | kA | 34.2 |

| 19 | Outer sheath material |

| HDPE |

| 20 | Nominal thickness of outer sheath | mm | 6.0 |

| 21 | Nominal overall diameter of cable | mm | 131.9 |

| 22 | Approx. weight of cable | kg/km | 25020 |

| 23 | Minimum bending radius | mm | 2640 |

| 24 | Max.D.C. Conductor resistance at20`C | Ω/km | 0.0129 |

| 25 | Nominal capacitance per phase | uF/km | 0.175 |

| 26 | Max. current rating in air at 40° C | A | 1656(2 circuit ,phase spacing 300, flat formation, a point earthed or cross connected) |

| 27 | Max. current rating in tunnel at 50° C | A | 1500(2circuit ,phase spacing 300, flat formation, a point earthed or cross connected , inside wide more than 1.8m, inside height more than 1.0m) |

| 28 | Max. conductor temperature on continuous | ℃ | 90 |

| 29 | Max. conductor temperature in short circuit | ℃ | 250(not exceed 5s) |

5. TEST REQUIREMENTS FOR EHV Power Cables

The cable testing shall be conducted in accordance with applicable standard of 400 kV Power Cables. The following test items shall be carried out in accordance with relevant IEC standards.

| No. | Test item |

| Routine tests | |

| 1 | Partial discharge test |

| 2 | Voltage test |

| 3 | electrical test on oversheath of the cable |

| Sample tests | |

| 1 | conductor examination |

| 2 | measurement of electrical resistance of conductor and of metal screen/sheath |

| 3 | measurement of thickness of insulation and oversheath |

| 4 | measurement of thickness of metal sheath |

| 5 | measurement of diameters |

| 6 | hot set test for XLPE insulation |

| 7 | measurement of capacitance |

6. PACKING PARTICULARS FOR 400 kV Power Cables

The cables shall be wound on steel drums. The indelible marking shall be printed on the surface of drum flange in accordance with customer requirements.

| Cable Type | Drum length(m) | Drum Dimensions (mm) | |||

| D | d | b | B | ||

| CU/XLPE/CWS/AL-PE/HDPE 220/400 kV 1× 1400 mm2 | 180 | 3800 | 3000 | 1950 | 2200 |

Note: The value [D" shall not contain the dimension of sealing plates.

Factory and Equipment

Package

1.Three Core Coper Conductor 2.Copper Wire Screened Cable 3.High Voltage Power Cable 4.HV XLPE Cable 5.XLPE Control Cable

Product Categories : High Voltage Power Cable