| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1000 Meter |

Model No.: USE-2

Brand: HUAYUAN YONGTONG

Type: Insulated

Conductor Type: Stranded

Application: Heating

Conductor Material: Copper

Sheath Material: PVC

Insulation Material: PVC

Material Shape: Round Wire

Range of Application: Cold-Resistant

Certification: ISO9001

Brand: HUAYUAN YONGTONG

Packaging: Drum

Productivity: 1000km/M

Transportation: Ocean,Land,Air

Place of Origin: Beijing,China

Supply Ability: 1000km/M

Certificate: CE,CCC,ISO

HS Code: 8544601200

Port: Tianjin Port,Shanghai Port,Qingdao Port

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

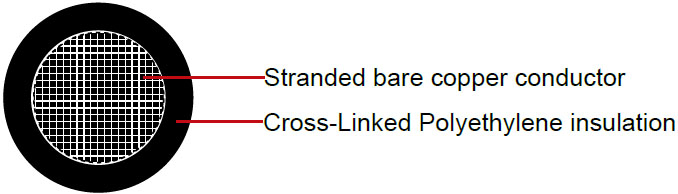

RHH/RHW-2, Wire, 600 V, Cu/XLPE

600 Volts ? Oxygen Free Copper Conductor ? Dead Soft Annealed Cross-Linked Polyethylene (XLPE) Insulation High-Heat and Moisture Resistant Sizes 6 through 4/0 AWG Also Rated SIS

RHW

R: Rubber insulation

This rubber outer layer is very important when it comes to copper cables, especially when those cables are utilized in possible hazardous environments. Performance Wire and Cable`s RHW-2 wires are insulated by cross-linked polyethylene. Even though the [R" stands for rubber, it also incorporates other neoprene insulations that XLPE falls under.

H: Heat resistance of 75 degrees Celsius

Again, cables must be able to withstand the elements. You`ll occasionally see [HH" on some wires, which details the wire`s ability to resist heat up to 90 degrees Celsius. The insulation`s length and width help determine its heat resistance. The thinner the XPLE is, the less resistant it is to heat.

W: Water resistant

Depending on location, this factor could be the most important for your wire. The [W" label even suggests that the cables can be submerged in water if needed. Even if the wire has [R," which means it is acceptable to use in damp locations, it is wise to keep these wires away from water if the [W" isn`t present. Wires without this [W" label are susceptible to failure and erosion when exposed to water and other liquids.

So, RHW cable is a wire is insulated by rubber or something else (XLPE), can withstand heat up to 75 degrees Celsius, and is water resistant. That`s why RHW cables are regularly found underground in wet locations. However, the NEC lists RHW-2 as having the ability to withstand heats of up to 90 degrees Celsius, a fact that puts our RHW-2 wires ahead of the competitions` regular RHW wires.

2.The difference between RHH and RHW cable

PROLINESAFETY.COM / 800.554.3424

? Pro-Line Type RHH or RHW-2 or USE-2 conductors are used with conduit as specified in the National Electrical Code1

? When used as Type USE-2, conductor is suitable for use as underground service entrance cable for direct burial at conductor temperatures not to exceed 90°C

? When used as RHH, conductor temperatures shall not exceed 90°C in dry locations

? When used as RHW-2 or USE-2, conductor temperatures shall not exceed 90°C in wet or dry locations

? Voltage rating for RHH or RHW-2 or USE-2 conductors is 600 volts

RHH RHW-2 USE-2 COPPER Building Wire

Underground Service Entrance Cable ? 600 Volts ? Oxygen Free Copper Conductor ? Dead Soft Annealed

Cross-Linked Polyethylene (XLP) Insulation High-Heat and Moisture Resistant

Sizes 6 through 4/0 AWG Also Rated SIS

RHH RHW-2 USE- 2

1 of 2

Applications

Pro-Line Type RHH or RHW-2 or USE-2 meets or exceeds UL Standard 44 (for RHH or RHW-2), UL Standard 854 (for USE-2), Federal Specification A-A-59544, and requirements of the National Electrical Code.

Standards and References

? Pro-Line Type RHH or RHW-2 or USE-2 copper conductors are annealed (soft copper.

? Insulation is an abrasion, moisture, heat, and sunlight resistant black cross-linkedpolyethylene (XLP).

Construction

Conductors shall be UL-listed Type RHH or RHW-2, suitable for operation at 600 volts or less in wet or dry locations, including direct burial in the earth. Conductors shall be annealed copper, cross-linked polyethylene (XLP) insulated. Type RHH or RHW-2 shall be PRO-LINE WIRE & CABLE or approved equal.

| CONDUCTOR SIZE | NUMBER OF STRANDS | INSULATION THICKNESS | NOMINAL O.D. | ALLOWABLE AMPACITIES | APPROX. NET WEIGHT PER 1000 FT. | ||

| (AWG or kcmil) | (mils) | (mils) | 60°C | 75°C | 90°C | (lbs) | |

| 14 | 7 | 45 | 160 | 15 | 15 | 15 | 21 |

| 12 | 7 | 45 | 177 | 20 | 20 | 20 | 30 |

| 10 | 7 | 45 | 201 | 30 | 30 | 30 | 44 |

| 8 | 7 | 60 | 262 | 40 | 50 | 55 | 72 |

| 6 | 7 | 60 | 297 | 55 | 65 | 75 | 106 |

| 4 | 7 | 60 | 344 | 70 | 85 | 95 | 156 |

| 2 | 7 | 60 | 400 | 95 | 115 | 130 | 238 |

| 1 | 19 | 80 | 484 | 110 | 130 | 150 | 309 |

| 1/0 | 19 | 80 | 523 | 125 | 150 | 170 | 381 |

| 2/0 | 19 | 80 | 567 | 145 | 175 | 195 | 472 |

| 3/0 | 19 | 80 | 617 | 165 | 200 | 225 | 586 |

| 4/0 | 19 | 80 | 673 | 195 | 230 | 260 | 729 |

| 250 | 37 | 95 | 751 | 215 | 255 | 290 | 867 |

| 300 | 37 | 95 | 804 | 240 | 285 | 320 | 1029 |

| 350 | 37 | 95 | 854 | 260 | 310 | 350 | 1191 |

| 400 | 37 | 95 | 899 | 280 | 335 | 380 | 1352 |

| 500 | 37 | 95 | 983 | 320 | 380 | 430 | 1674 |

| 600 | 61 | 110 | 1089 | 355 | 420 | 475 | 2012 |

| 750 | 61 | 110 | 1191 | 400 | 475 | 535 | 2492 |

| 1000 | 61 | 110 | 1340 | 455 | 545 | 615 | 3288 |

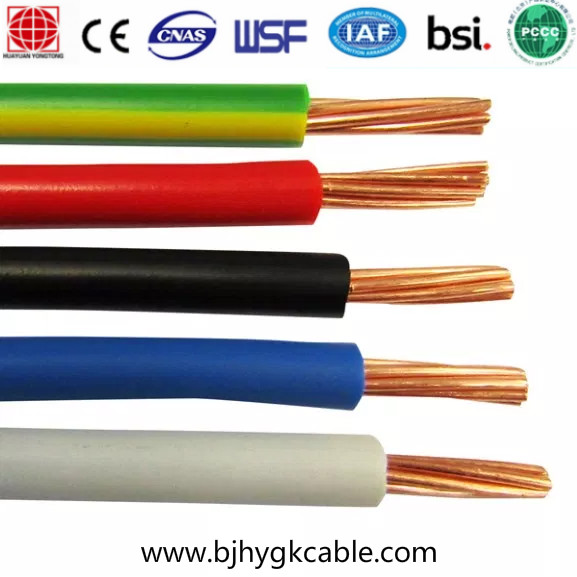

4. The products picture

Technical Parameter of wire cable electrical

SIZE AWG CROSS SECTION STRANDING number of INSULATION EXTERNAL TOTAL WEIGHT MCM AL mm2 wire x diametre mm THICKNESS

mm DIAMETER

mm KG/KM 20 0.52 1×0.813 0.76 2.33 9.81 18 0.82 1×1.02 0.76 2.54 13.16 16 1.31 1×1.29 0.76 2.81 18.1 14 2.08 1×1.63 0.76 3.15 26.1 12 3.31 1×2.05 0.76 3.57 38.3 10 5.26 1×2.59 0.76 4.11 57.4 8 8.34 1×3.26 1.14 5.54 95.2 14 2.08 7×0.62 0.76 3.38 27.8 12 3.31 7×0.78 0.76 3.86 40.1 10 5.26 7×0.98 0.76 4.46 59.9 8 8.37 7×1.23 1.14 5.97 105.2 6 13.3 7×1.55 1.52 7.69 170.4 4 21.15 7×1.96 1.52 8.92 255.5 2 33.62 7×2.47 1.52 10.45 388.9 1 42.36 7×2.78 2.03 12.4 482.9 1/0 53.49 19×1.89 2.03 13.51 621 2/0 67.43 19×2.12 2.03 14.66 778 3/0 85.01 19×2.39 2.03 16.01 934 4/0 107.2 19×2.68 2.03 17.46 1159 250 127 37×2.09 2.41 19.45 1368 300 152 37×2.29 2.41 20.85 1623 350 177 37×2.47 2.41 22.11 1876 400 203 37×2.64 2.41 23.3 2128 500 253 37×2.95 2.41 25.47 2631 600 304 37×3.23 2.79 28.19 3174 650 329 37×3.37 2.79 29.17 3345 700 355 37×3.49 2.79 30.01 3609

Based on 40℃ ambient air temperature.

The above information is from the following sources:

• IEC 60287 Electric cables – Calculation of the current rating (all Parts)

• IEC 60364 Electrical installations of buildings

• IEC 60228 Conductors of insulated wire cables

Testing Picture

Product Categories : Electrical Wire Cable