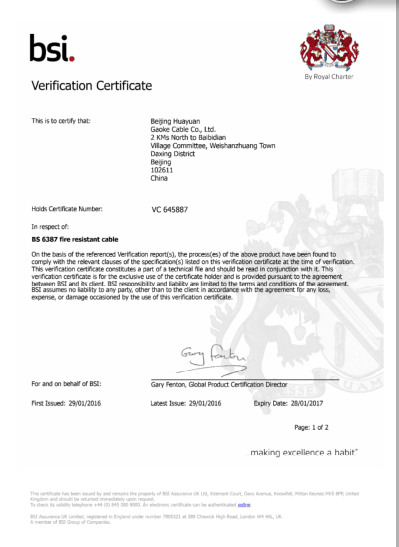

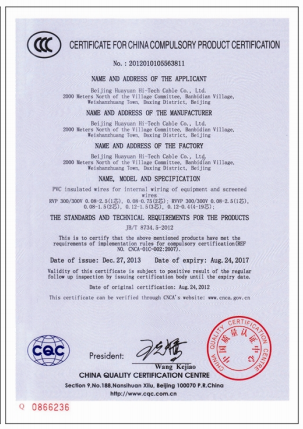

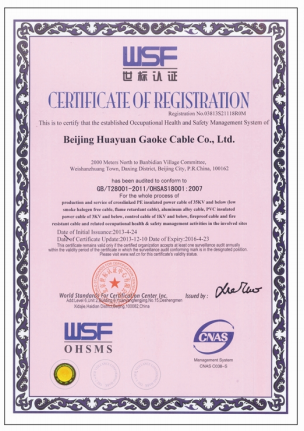

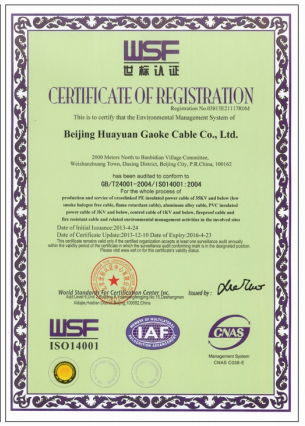

Our company mainly engaged in Fire Resistant Cable,Fire Proof Cable,High Voltage Power Cable,Control Cable,Building Wire,Low Voltage Power Cable,Copper Cable and so on, first-class technology, quality and safety!

Huayuan Gaoke Cable Co.,Ltd.

Fire Resistant Cable manufacturer / supplier

, offering Fire Proof Cable,High Voltage Power Cable, etc.