Huayuan Gaoke Cable Co.,Ltd.

66KV Copper Conductor Semi-conducting Tape Cable,Corrugated Aluminum Sheath PVC Outer Sheath Cable,CU/XLPE/CORRPUGATED AL/HDPE Cable

Huayuan Gaoke Cable Co.,Ltd.

66KV Copper Conductor Semi-conducting Tape Cable,Corrugated Aluminum Sheath PVC Outer Sheath Cable,CU/XLPE/CORRPUGATED AL/HDPE Cable

| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 500 Meter |

Model No.: YJV

Brand: HUAYUAN YONGTONG

Type: Insulated

Conductor Type: Stranded

Application: Underground

Conductor Material: Copper

Sheath Material: PVC

Insulation Material: XLPE

Material Shape: Round Wire

Range of Application: LSOH

Certification: ISO9001

Brand: HUAYUAN YONGTONG

Packaging: DRUMS

Productivity: 100KM/M

Transportation: Ocean,Land,Air

Place of Origin: BEIJING CHINA

Supply Ability: 100KM/M

Certificate: CE ISO CCC

HS Code: 8544601300

Port: Shanghai Port,Tianjin Port,Qingdao Port

Payment Type: L/C,T/T,D/P,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

TECHNICLA DATA SHEET FOR 66 kV 240 SQmm POWER CABLE

| NO. | ITEM | UNIT | DATA |

| 1 | Name of Manufacturer: | Beijing Huayuan Gaoke | |

| Cable Co.,Ltd. | |||

| 1.2 | Country of Manufacturer: | China | |

| 2 | Which type of manufacturing process viz. Continuous Catanery Vulcanisation (CCV) or vertical Catanery Vulcanisation system (VCV) or horizontal MDCV will be used to ensure circularity and concentricity of the extruded layers around the conductor. | VCV | |

| 3 | Type of Cable: | CU/XLPE/CORRUGRTED AL/PVC | |

| 4 | Rated nominal voltage | kV | 38/66 |

| 5 | Rated Maximum voltage | kV | 72.5 |

| 6 | Nominal cross-sectional area of Conductor | Sq.mm | 240 |

| 7 | Conductor | ||

| 7.1 | Material | Copper | |

| 7.2 | Shape & formation | Circular | |

| 7.3 | Diameter of conductor | mm | 18.4 |

| 7.4 | Dia.Of Single Wire/Number of strands | mm | 36/3.0 |

| 8 | Conductor Screen | ||

| 8.1 | Material | Semi conductive tape+ Super slippery semi conductive material | |

| 8.2 | Thickness of seim-conductor tape | mm | 0.12 |

| 8.3 | Thickness of seim-conductor XLPE | mm | 1.2 |

| 8.4 | Diameter of Sime-conductor(Approx.) | mm | 21.2 |

| 9 | Insulation | ||

| 9.1 | Material | Super clean XLPE | |

| 9.2 | Insulation Thickness(Min.Avg.) | mm | 14 |

| 9.3 | Diameter of Insulation(Approx.) | mm | 49.2 |

| 10 | Insulation Screen | ||

| 10.1 | Material | Super slippery semi conductive material | |

| 10.2 | Insulation Screen Thickness(Approx.) | mm | 1.2 |

| 10.3 | Diameter of Sime-Insulation(Approx.) | mm | 51.6 |

| 11 | Water blocking tape | ||

| 11.1 | Material | Semi conductor water blocking tape | |

| 11.2 | Approximate thickness | mm | 4 |

| 11.3 | Diameter of inner sheath (Approx.) | mm | 58.6 |

| 12 | Metallic Screen: | ||

| 12.1 | Material | Corrugated Al | |

| 12.2 | Thickness of the Corrugated Al | mm | 2 |

| 12.4 | Diameter of the cable across the metallic screen(Approx.) | mm | 71.6 |

| 13 | Bedding tape | ||

| 13.1 | Material | Semi-conducting bedding tape | |

| 13.2 | Approximate thickness | mm | 4 |

| 13.3 | Diameter of bedding (Approx.) | mm | 58.6 |

| 14 | Armouring | ||

| 14.1 | Material | Corrugated Al sheath | |

| 14.2 | Approximate thickness | mm | 2 |

| 14.3 | Diameter of armouring (Approx.) | mm | 71.6 |

| 15 | Outer Sheath | ||

| 15.1 | Material | PVC | |

| 15.2 | Outer Sheath Thickness(Nominal) | 4 | |

| 15.3 | Over Diameter(Approx.) | 80 | |

| 16 | Conductor Weight | kg/km | 2136 |

| 16.1 | Total Cable Weight (Approx.) | kg/km | 6950 |

| 17 | Minimum Bending Radius | ||

| 17.1 | During Installation | mm | 1600 |

| 17.2 | Installed | mm | 1500 |

| 18 | Maximum Pulling Tension | ||

| 18.1 | Of Conductor | kN | 16.8 |

| 19 | Continuous current rating under the specified installation and operating conditions. Conductor temperature 90° C . Ground temperature 35° C and depth of laying 1500 mm | ||

| 19.1 | In Air | Amp | 352 |

| 19.2 | In Ground | Amp | 259 |

| 19.3 | In pipeline | Amp | 228 |

| 20 | Maximum value of electric stresses at the conductor screen (Calculation to be shown separately) | kV/mm | 4.28 |

| 2.01 | Maximum value of dielectric stress at the insulation | kV/mm | 1.83 |

| 21 | Short circuit capacity of conductor for 1/2/3 second assuming conductor temperature of 90 ° C prior to short circuit and 250 ° C during short circuit | ||

| 21.1 | 1.0 Secs | kA | 34.4 |

| 21.2 | 2.0 Secs | kA | 24.5 |

| 21.3 | 3.0 Secs | kA | 20 |

| 22 | Short circuit capacity of metallic screen for 1/2/3 second at screen temperature of 80 ° C prior to short circuit and 200 ° C during short circuit | ||

| 22.1 | 1.0 Secs | kA | 42.5 |

| 22.2 | 2.0 Secs | kA | 30.9 |

| 22.3 | 3.0 Secs | kA | 25.7 |

| 23 | Ionization factor at 50 Hz. (Tan Delta) | 0.001 | |

| 24 | Screen voltage under maximum operating conditions assuming all circuits connected | kV per km | 0.1 |

| 25 | TEST | ||

| 25.1 | Maximum D.C. resistance of conductor per km. at 20 degree C. | Ohm | 0.0754 |

| 25.2 | Maximum A.C. resistance of conductor per km. at 90 degree C. | Ohm | 0.097 |

| 25.3 | Maximum electrostatic capacitance per km. of cable. | μF | 0.152 |

| 25.4 | Partial discharge at 1.50 Uo | pc | ≤ 5 |

| 25.5 | A.C. Enduring Test voltage 2.5U0/ hours | kV/mim | 120/30 |

| 26.6 | D.C.Out sheath Enduring Test voltage | kV/mim | 10kV/1min |

| 25.7 | Impulse test voltage | kV | 350 |

| 26 | Approximate drum dimension (dia & width) | mm/mm | 3200*2200 |

| 27 | Maximum length of cable in a drum (Metres) | m | 1100 |

| 28 | Minimum length of cable in a drum (Metres) | m | 1000 |

| 29 | Approximate gross weight of cable in a drum | TON | 7.2 |

| 30 | Expected Cable life. | Year | 30 |

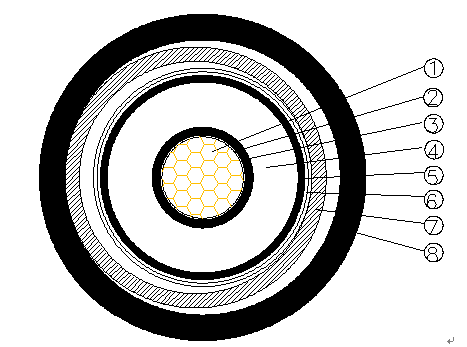

CU/XLPE/ Corrugated Al /PVC 38/66kV 1C 240 mm2

CU/XLPE/CORRPUGATED AL/HDPE 38/66(72.5) kV 1C 240 mm2

| Construction | Thickness(mm) | Diameter(mm) |

| 1--Conductor |

| 18.4(+0.1,-0.1) |

| 2--Semi-conducting tape | 0.12 | 18.8 |

| 3--Conductor screen | 1.2 | 21.2 |

| 4--XLPE insulation | 14.0 | 49.2(+1.0,-1.0) |

| 5--Insulation screen | 1.2 | 51.6 |

| 6--Semi-conducting bedding tape | 4.0 | 58.6 |

| 7--Corrugated Al sheath (include asphaltum) | 2.0 | 71.6 |

| 8-PVC outer sheath (including graphite) | 4.0 | 80.0(+2.5,-2.5) |

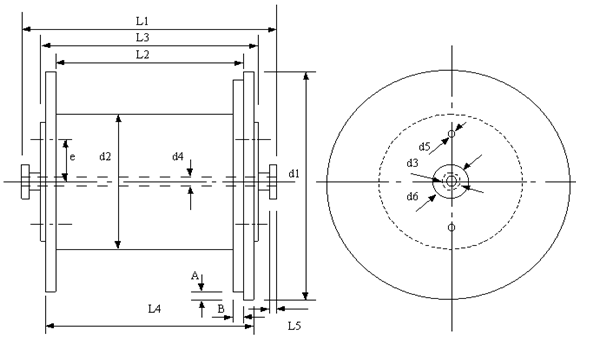

Drum

d1:3200mm

L1:2200mm

500m per drum

H :3200mm

L :3200mm

W:2200mm

Wight: 800 kg

Advanced Manufacturing Equipments

Advanced Testing Equipments

The company introduced the world's advanced level wire & cable production and testing equipment, such as DV-6E spectrum analyzer, online micro pore impurity tester, etc.

Advanced Testing Equipment Guarantee High Quality Production

1.69kv Cable 2.High Voltage Power Cable 3.Three Core Copper Conductor 4.Single Core Aluminium Conductor 5.Hgih Quality Aluminum Alloy 6.Aluminium Alloy Casing Cable 7.HV XLPE Cable

Product Categories : High Voltage Power Cable