Huayuan Gaoke Cable Co.,Ltd.

Single Core 1200mm2 HV Power Cable KEMA Test Report,Maximum 123KV CABLE,With DTS Fibre Cable

Huayuan Gaoke Cable Co.,Ltd.

Single Core 1200mm2 HV Power Cable KEMA Test Report,Maximum 123KV CABLE,With DTS Fibre Cable

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Min. Order: | 1000 Meter |

Model No.: YJLW03

Brand: HUAYUAN YONGTONG

Type: Insulated

Conductor Type: Stranded

Application: Underground

Conductor Material: Copper

Sheath Material: Crosslinking

Insulation Material: XLPE

Material Shape: Round Wire

Range of Application: Refractory

Certification: ISO9001

Brand: HUAYUAN YONGTONG

Packaging: Drum

Productivity: 1000km/M

Transportation: Ocean,Land,Air

Place of Origin: Beijing,China

Supply Ability: 1000km/M

Certificate: CE,CCC,ISO,KEMA

HS Code: 8544601400

Port: Tianjin Port,Shanghai Port,Qingdao Port

Payment Type: L/C,T/T,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT

Specification:

110 kV XLPE Cable Data

| Item Nº | Description | Unit | Required Data | Tenderer/ Contractor Data |

|

| Manufacturer | - | Bidder offers specific | Beijing Huayuan Cable Co.,Ltd. |

|

| Manufacturer reference/designation | - | - | IEC 60840 |

|

| Manufacturing and test standards in accordance with IEC and section 2 of this document. | - | Yes | YES |

| 2.1 | Insulation strength |

|

|

|

|

| Nominal operating voltage, phase to earth, Uo | kV | 64 | 64 |

|

| Nominal operating voltage, phase to phase | kV | 110 | 110 |

|

| Maximum operating voltage, phase to phase, U,n | kV | 123 | 123 |

|

| Lightning impulse withstand voltage (peak) | kV | 550 | 550 |

|

| Power frequency withstand voltage | kV | 230 | 160 |

| 2.2 | Conductor |

|

|

|

|

| Material | - | copper | copper |

|

| Nominal cross-section | mm2 | 1200 | 1200 |

|

| Shape | - | Milliken(strandedandsegmented) | Milliken(stranded and segmented) |

|

| Nominal diameter | mm |

|

|

|

| Number of segments | - | four, five or six | five |

| 2.3 | Conductor screen ( inner shielding layer) |

|

|

|

|

| Material | - |

| wrapping semi-cond.tapes +extruded semi-cond. XLPE compound |

|

| Visible irregularities on outer surface | µm | ≤ 60 | ≤ 80 |

|

| Production method

|

| Extrusion semi-Conducting surrounding | Extrusion semi-Conducting |

|

| Resistivity | Ohm.m | ≤ 1000 | ≤ 1000 |

|

| Wall thickness |

|

|

|

|

| • average value | mm | 0.8 | ≥1.2 |

|

| • min value | mm | 80% of average value | 1.0 |

|

| Nominal outer diameter | mm |

| 46.1 |

| 2.4 | Insulation |

|

|

|

|

| Material |

| XLPE | XLPE |

|

| Maximum dielectric stress at conductor screen | kV/mm | 10.5 | 10.5 |

|

| Maximum dielectric stress at insulation screen | kV/mm | 5.5 | 5.5 |

|

| inner diameter of insulator | mm |

| 46.1(nominal) |

|

| external diameter of insulator | mm |

| 78.1(nominal) |

|

| maximum thickness | mm | 16 | 16.8 |

|

| Min tensile strength (without aging) | N/mm2 | 12.5 | 12.5 |

|

| Minimum wall thickness

| -

| > 90% of average |

14.4mm |

|

| Maximum wall thickness

|

| (tmax-tmin)/tmax ≤ 0.15 | (tmax-tmin)/tmax ≤ 0.15 |

|

| Max. visible irregularities | µm | ≤ 50 | ≤ 80 |

|

| Max. partial discharge | pC | ≤ 5 | ≤ 5 |

|

| Thermal resistivity according to IEC 287 | K.m/W |

| 3.5 |

|

| Max losses/tan delta | - |

| 0.001 |

|

| Electrical field stress |

|

|

|

|

| • Inner shielding layer | kV/mm | ≤ 10.5 | 5.27 |

|

| • Outer shielding layer | kV/mm | ≤ 5.5 | 3.11 |

|

| Min tensile strength | N/mm2 | 12.5 | 12.5 |

|

| Nominal outer diameter | mm |

| 78.1 |

| 2.5 | Insulation screen ( outer shielding layer ) |

|

|

|

|

| Average wall thickness | mm | > 0.8 | > 0.8 |

|

| Resistivity | Ohm.m | ≤ 500 | ≤ 500 |

|

| Visible irregularities | mm | ≤ 80 | ≤ 80 |

|

| Difference between max and min diameter | mm | ≤ 1.2 | ≤3.0 |

|

| Nominal outer diameter | mm |

| 80.1 |

| 2.7 | Longitudinal water-sealing swell layer |

|

|

|

|

| • Swelling powder | - | Yes | NO |

|

| • Swelling tape | - | Yes | Yes |

|

| • Water tightness ( pressure withstand) | -

| ≥ 1m water Level | ≥ 1m water Level |

|

| Nominal outer diameter | mm |

| 86.1 |

| 2.8 | Metal Sheath |

|

|

|

|

| Short circuit capability (1 sec) | KA | 40 | ≥40 |

|

| Type | - |

|

|

|

| Aluminium laminated sheath |

|

|

|

|

| • construction method | - |

| NA |

|

| • Material/composition of material | - |

| NA |

|

| • Nominal cross section of sheath | mm2 |

| NA |

|

| • Wall thickness | mm |

| NA |

|

| • Average thickness | mm |

| NA |

|

| or |

|

|

|

|

| corrugated aluminium sheath |

|

|

|

|

| • construction method | - | Annular ringtype | Annular ring type |

|

| • Material/composition of material |

|

| Welding corrugated aluminium sheath |

|

| • Nominal cross section of sheath | mm2 |

| 785 |

|

| • Wall thickness | mm |

| 2.4(nominal) |

|

| • Average thickness | mm |

| ≥2.1 |

|

| Nominal outer diameter | mm |

| 112.0 |

| 2.9 | Corrosion proof coating |

|

|

|

|

| Material | - | Bitumen | Bitumen |

|

| Wall thickness | mm |

| 0.25 |

|

| Nominal outer diameter | mm |

| 112.5 |

| 2.10 | Outer sheath ( protective layer) |

|

|

|

|

| Material |

| PE | MDPE |

|

| Max/min wall thickness | mm |

| 5.8/4.1 |

|

| Nominal wall thickness | mm | < 4.5 | 5.0 |

|

| Thermal resistivity | K.m/W |

| 3.6 |

|

| Maximum permissible temperature | °C |

|

|

|

| (1) normal continuous operation | °C |

| 90 |

|

| (2) emergency (short time) operation | °C |

| 105 |

|

| (3) short circuit (very short time) | °C |

| 250(not exceed 5s) |

|

| Colour | - | Black | Black |

|

| Tensile strength without aging | N/mm2 | 10 | 10 |

|

| Nominal outer diameter | mm |

| 122.5 |

| 2.11 | Transmission capacity |

|

|

|

|

| one cable circuit in operation | MVA | 202 | 202 |

|

| two cable circuits in operation(*) | MVA | 2 x 166 | 2 x 166 |

|

| (*) Bidder shall state the maximum transmission capacity when two cable circuit in operation |

|

|

|

| 2.12 | Reactive power requirements |

|

|

|

|

| Maximum charging current | A/km | 12 | 12 |

| 2.13 | Short circuit currents |

|

|

|

|

| Three phase fault current, 1 sec | kA | ≥ 40 | ≥ 40 |

|

| Single phase fault current, 1 sec | kA | ≥ 40 | ≥ 40 |

|

| Permissible short circuit currents of cable ( pre-fault conditions: max permissible conductor temperature ) |

|

|

|

|

| (1) for conductor (three phase fault current, 1 sec) | kA |

| 172 |

|

| (2) for screen / metal sheath (single phase fault current, 0.5 sec) | kA |

| 101 |

|

| (3) for screen / metal sheath (single phase fault current, 1 sec) | kA |

| 73 |

|

| (4) for screen / metal sheath (single phase fault current, 3 sec) | kA |

| 44 |

|

| Max conductor temperature for three phase/earth fault | °C | 250 | 250(not exceed 5s) |

| 2.14 | Electrical Parameters |

|

|

|

|

| Copper purity | - | 99.99% | 99.99% |

|

| Nominal resistance | Ohm/km |

|

|

|

| DC resistance of conductor at 20 °C (R0) | Ohm/km | 0.0151 | |

|

| DC resistance of conductor at 90 °C (R`) | Ohm/km |

| ≤0.0193 |

|

| AC resistance of conductor at 90 °C (R) | Ohm/km |

| ≤0.0201 |

|

| DC resistance of conductor of metal sheath at 20 °C | Ohm/km |

| ≤0.0396(Al sheath) |

|

| DC resistance of conductor of copper wire screen at 20 °C | Ohm/km |

| NA |

|

| AC resistance of conductor at Thermal of conductor at demand current (915A) (RIyc) | Ohm/km |

| 0.0201 |

|

| Max field strength at conductor screen at U0=64 kV | kV/mm |

| 10.5 |

|

| Charging current per phase at operating voltage | A/km |

| 12 |

|

| Charging power per circuit at operating voltage | kVar/km |

| 1320 |

|

| Dielectric loss factor at 20/90 °C | p.u. |

| 0.001/0.001 |

|

| Inductance for flat formation (275 mm between phases) |

|

|

|

|

| Phase A1 | mH/km |

| 0.637 |

|

| Phase B1 | mH/km |

| 0.430 |

|

| Phase C1 | mH/km |

| 0.637 |

|

| Reactance for flat formation (275 mm between phases) |

|

|

|

|

| Phase A1 | Ohm/km |

| 0.201 |

|

| Phase B1 | Ohm/km |

| 0.135 |

|

| Phase C1 | Ohm/km |

| 0.201 |

|

| Surge impedance of cable | Ohm |

| 38.7 |

|

| Max positive sequence & negative sequence impedance |

|

|

|

|

| (1) with sheath current | Ohm/km |

| 0.0616+j0.0249 (flat formation) |

|

| (2) without sheath current | Ohm/km |

| 0.0201+j0.153 (flat formation) |

|

| Max zero sequence impedance (return currents in sheath) | Ohm/km |

| 0.168+j1.654 (flat formation) |

|

| Temperature of conductor at demand current (θIyc) | °C |

| 90 |

|

| External diameter of conductor (dc) | mm |

| 42.1(nominal) |

|

| Diameter over insulation (Di) | mm |

| 78.1(nominal) |

|

| Insulation thickness (ti) | mm |

| 16.0(nominal) |

|

| Inner diameter of insulation (Di - ti) | mm |

| 46.1(nominal) |

|

| Loss factor of insulation (tan δ) |

|

| 0.001(max.) |

|

| External diameter of metal sheath (Ds) | mm |

| 112.0(nominal) |

|

| Thickness of the sheath (t s ) | mm |

| 2.4(nominal) |

|

| Mean diameter of sheath or screen (d) | mm |

| 104.1 |

|

| a.c. resistance of cable sheath or screen (Rs) | Ohm/km |

| 0.049(at 65℃) |

|

| Sheath resistivity at 200C (ρs) | Ohm.km |

| 2.83 ×10-5 |

|

| Reactance of sheath (X1) | Ohm/km |

| 0.130 |

|

| Ratio of the losses in the sheath and amour (if any). (λ1) |

|

| 0.167 flat formation) |

|

| Ratio of the losses in the sheath and amour (if any) at operating current specified in bidding document. (λ1yc) |

|

| 0.167(flat formation) |

|

| Ratio of the losses in one sheath caused by circulating currents in the sheath to losses in one conductor (λ1`) |

|

| 0(flat formation, cross connected) |

|

| Ratio of the losses in one sheath caused by eddy currents to the losses in one conductor (λ1"). |

|

| 0.167(flat formation) |

| 2.15 | Current ratings |

|

|

|

|

| Max permissible continuous current carrying capacity per circuit with cross-bonding, laid in HDPE pipes 225 mm diameter, buried (operation of one circuit) | A | 1059 | 1059(1circuit,phase spacing 275, flat formation, cross connected , depth of laying 3100 mm ,thermal resistivity of soil 1.0 k.m/W,30℃,in pipe,pipe outer diameter 225mm) |

|

| Max permissible continuous current carrying capacity per circuit with cross-bonding, laid in HDPE pipes 225 mm diameter, buried (operation of two circuits) | A | 871 | 871(2circuit,phase spacing 275, flat formation, cross connected , depth of laying 3100 mm ,thermal resistivity of soil 1.0 k.m/W,30℃,in pipe,pipe outer diameter 225mm) |

|

| Max conductor temperature at rated current | °C |

| 90 |

|

| Max continuous conductor temperature | °C | 90 | 90 |

|

| Max permissible transmission capacity at operating voltage for |

|

|

|

|

| (1) one circuit in operation | MVA |

| 202 |

|

| (2) two circuits in operation | MVA |

| 2 x 166 |

|

| Rated minimum continuous current per circuit (operation of one circuit) | A |

| 1059(1circuit,phase spacing 275, flat formation, cross connected , depth of laying 3100 mm ,thermal resistivity of soil 1.0 k.m/W,30℃ in pipe, pipe outer diameter 225mm) |

|

| Rated minimum continuous current per circuit (operation of both circuit) | A |

| 871(2circuit,phase spacing 275, flat formation, cross connected , depth of laying 3100 mm ,thermal resistivity of soil 1.0 k.m/W,30℃ in pipe ,pipe outer diameter 225mm) |

|

| System load factor | - | 0.8 | 0.8 |

| 2.16 | Cable losses |

|

|

|

|

| Max continuous current, cross-bonding, nominal voltage, 40 °C |

|

|

|

|

| (1) conductor | kW/km | Bidder offers specific | 22.54(I=1059A,per phase) |

|

| (2) dielectric | kW/km | Bidder offers specific | 0.33(per phase) |

|

| (3) metal screen | kW/km | Bidder offers specific | NA |

|

| (4) metal sheath | kW/km | Bidder offers specific | 3.76(I=1059A,per phase) |

|

| (5) total losses at rated capacity (total of 1,2,3 and 4 ) | kW/km | Bidder offers specific | 26.63(per phase) |

| 2.17 | Mechanical data and dimension of cable |

|

|

|

|

| Outer diameter (De) | mm |

| 122.5(nominal) |

|

| Net weight | Kg/km |

| 18100(approx.) |

|

| Max delivery length (according site conditions) | m |

| 1000 |

|

| Min permissible bending radius (according site conditions) | m |

| 2.45 |

|

| Max permitted pulling tension | kN |

| 84(of conductor) |

| 2.18 | Longevity of cable | years | > 30 | > 30 |

| 2.19 | Minimum bending radius |

|

|

|

|

| - at laying (R1) |

| R1=20*(d+D)*1.05 R2=1.5R1 d: conductor diameter D: outer cable diameter | R1=20*(d+D)*1.05 R2=1.5R1 d: conductor diameter D: outer cable diameter

|

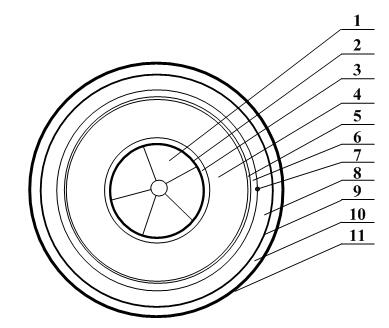

Conductor structure

CU/XLPE/CAS/MDPE 64/110kV 1x1200 mm2

| Structure | Nominal Thickness(mm) | Nominal Diameter(mm) |

| 1 Five(5) segmental copper conductor | / | 42.1± 0.6 |

| 2 Semi-conductor tape | 0.14 | 43.1 |

| 3 Conductor screen (wrapped +extrusion) | 2.0 | 46.1 |

| 4 XLPE Insulation | 16.0 | 78.1±1.5 |

| 5 Insulation screen | 1.0 | 80.1±1.5 |

| 6 Semi-conductor water blocking tape | 2.0 | 86.1 |

| 7. Fiber optic cable | One root 2 core multimode 50/125μm round armored fiber optic cable |

|

| 8 Corrugated aluminium sheath(welding) | 2.4 | 112.0 |

| 9 Anti corrosion layer (Bitumen) | 0.25 | 112.5 |

| 10 MDPE Outer sheath | 5.0 | 122.5 |

| 11 Semi-cond. Coating(Graphite) |

| 122.5±3.0 |

Our company

Workshop

Package

Delivery and Payment

Honor

Customer

1.Five Core Copper Conductor 2.Three Core Copper Conductor 3.Low Smoke Halogen Free Cable 4.Halogen Free Cable 5.Low Smoke Cable 6.Zero Halogen Cable

Product Categories : High Voltage Power Cable